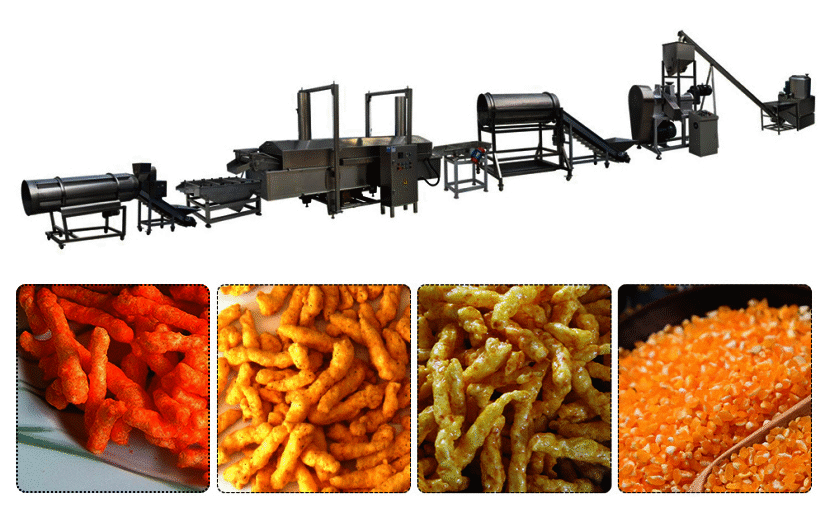

85KW INSTALLED POWER KURKURE MANUFACTURING MACHINE , CORN SNACKS MAKING MACHINE EXTRUSION TYPE

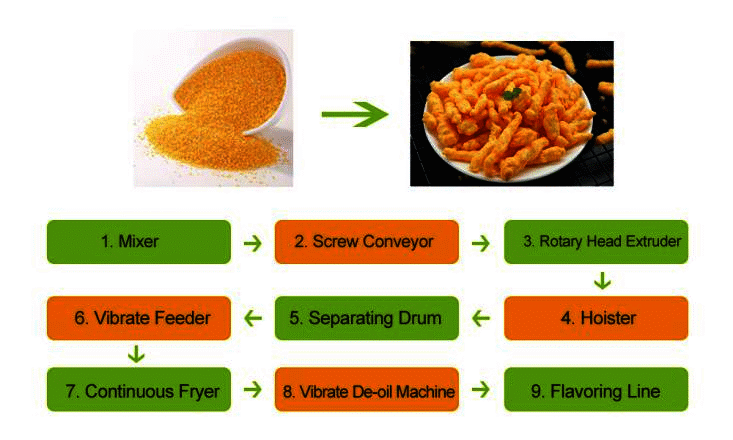

As we all know, the extruder of the kurkure manufacturing machine is the core machine of the production line. What are the advantages of our company's extruder? Let's take a look at the extruder technology and the advantages of our products!Nik Naks Making Machinery mainly use corn grits as material.In the flour mixer with water and fed to the rotary die extruder. In the extruder, due to excessheat andpressure from the screws the meal gets heated and the moisture content gets reduced.The meal passes through the die and gets cut by the cutting knifes into required lengths.The kurkure are fried in cooking oil and then cooled before flavoring. Seasoning is sprayed on the kurkure to improve their taste.

85KW INSTALLED POWER KURKURE MANUFACTURING MACHINE , CORN SNACKS MAKING MACHINE EXTRUSION TYPE Specifications :

| Price | Contact us |

| Brand Name | LOYAL |

| Place of Origin | China |

| Min.Order Quantity | 1 |

| Payment Terms | T/T,L/C,D/P |

| Supply Ability | 1000 |

| Delivery Detail | 10-25 working days. |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

85KW INSTALLED POWER KURKURE MANUFACTURING MACHINE , CORN SNACKS MAKING MACHINE EXTRUSION TYPE Detail Introduction :

As we all know, the extruder of the kurkure manufacturing machine is the core machine of the production line. What are the advantages of our company's extruder? Let's take a look at the extruder technology and the advantages of our products!

Extrusion technology in kurkure manufacturing machine is a new processing technology that integrates mixing, stirring, crushing, heating, cooking, sterilization, puffing and molding, and can realize a series of simultaneous and continuous operation of a series of units. Its process is simple, low energy consumption, low cost, and has The characteristics of multi-function, high yield and high quality play an important role in thinning coarse grains, improving the taste of coarse grains, inactivating bad factors, and improving protein digestibility. There are many kinds of products after extrusion, the preservation rate and digestibility of nutrients are high, and it is convenient to eat.

KURKURE MANUFACTURING MACHINE PRINCIPLE:

The material is fed into the extruder, and driven by the screw and screw, the material moves forward in an axial direction. At the same time, due to the mechanical friction between the screw and the material, the material and the barrel, and the inside of the material, the material is squeezed, stirred, and sheared intensively. As a result, the material is further refined and homogenized. With the gradual increase of the internal pressure of the machine cavity, the temperature correspondingly continues to rise.Under the conditions of high temperature, high pressure and high shearing force, the physical properties of the material have changed, from powder to paste, and starch gelatinization, After lysis, the protein is denatured and reorganized, the fiber is partially degraded and refined, the pathogenic bacteria are killed, and the toxic components are inactivated. When the paste material is ejected from the die hole, under the action of the strong pressure difference, the water vaporizes rapidly, and the material is expanded to form a loose, porous, and crispy puffed product, so as to achieve the purpose of extrusion and puffing.

The pellet/potato chips/extrusion frying production line is designed to make pellets, potato chips, and fried food through the food expander extruder. The raw material can be potato starch, corn starch, flour, tapioca starch and the like. Through extruder extrusion and mold modeling, snacks can be made into shellfish, spirals, spirals, square tubes and other shapes. Seasoning with dried, deep-fried, and flavor powder, you can get delicious snack foods. Changing the forming machine can produce 3D pellets, tetanus potato chips, potato chips, shrimp chips, etc.

Material: All machines are made of food grade stainless steel.

KURKURE MANUFACTURING MACHINE PRODUCT FEATURES AND ADVANTAGES:

1. The series of twin-screw extruders are mainly composed of a feeding system, an extrusion system, a rotary cutting system, a heating system, a transmission system, a lubrication system, and a control system.

2. The feeding system, drive system, and rotary cutting system adopt variable frequency speed regulation, which has strong power and stable operation.

3. Automatic lubrication and forced cooling to ensure the stable operation of the extruder.

4. For different raw materials, menus, twin-screw feeding system, uniform feeding, stable and reliable.

5. The screw is processed by a special process, which is wear-resistant, anti-fatigue and has a long service life.

6. Different screw length-to-diameter ratio structures meet different process requirements.

We have the most advanced technology applied to the kurkure manufacturing machine, and the innovatively developed extruder for the kurkure manufacturing machine. The process of our kurkure manufacturing machine is roughly the same.

The kurkure manufacturing machine is a special extrusion process. The corn grits material is moistened with water in a flour mixer and conveyed into rotary head extruder. The kernels are then extruded and twisted into a curled shape. A cutting knife cuts them to our desired length. After cutting, the corn sticks are fried in a deep fryer and then cooled by conveying cooling or shaking and filtering the oil before being seasoned. Finally, they are packed in a packaging machine. The kurkure manufacturing machine works automatically and is superbly automated.

| Kurkre Snacks Machinery List | ||

| NO. | NAME | QUANTITY |

| 1 | MIXER | 1 SET |

| 2 | SCREW CONVEYOR | 1 SET |

| 3 | ROTARY HEAD EXTRUDER | 1 SET |

| 4 | HOISTER | 1 SET |

| 5 | SEPARATING AND COOLING ROTARY DRUM | 1 SET |

| 6 | HOISTER | 1 SET |

| 7 | FIVE-LAYER DRYER | 1 SET |

| 8 | FOOD GRADE MACHINE | 1 SET |

| ROLLING FLAVORING MACHINE | 1 SET | |

| SEASONING PODWER MACHINE | 1 SET | |

| OIL SPRAYER | 1 SET | |

Customer Cases For Kurkur Snack Food Production Line For Factory In 2021

Shandong Loyal Industrial relies on complete product specifications, excellent product quality and professional services. It has been widely recognized by customers, obtained a good brand image, has mature and stable sales channels, and accumulated a large number of high-quality customers. At present, the company's products are in short supply and are exported to Asia, Europe, North America, Africa, South America and Oceania, with customers in more than 50 countries and regions around the world. If you are interested in the Kurkur Snack Food Production Line, please contact LOYAL immediately, we will provide you with high-quality formulations of Kurkur Snack Food Production Line, professional technical process guidance, and a full range of professional market analysis.

Customer Cases For Kurkur Snack Food Machine For Factory In 2021 | |

| 1 | 1t/h Ce Certificated Industrial Energy Efficient Kurkur Snack Food Machine Sold In Russia Customer Factory |

| 2 | 1t/h Kurkur Snack Food Machine For Sale In Puerto Rico Customer Factory |

| 3 | 1t/h Kurkur Snack Food Machine Installed in Customer Factory For Sale In Bolivia Customer Factory |

| 4 | Senegal 1t/h Kurkure/cheetos/niknak corn curls machine Dryer Machine |

| 5 | 1t/h Energy Saving Large Industrial Kurkure/Cheetos/Niknak Corn Curls Machine For Sale In Côte d'Ivoire |

| 6 | China 300t/Year Tunnel Microwave Wood Dryer Timber Drying Machine |

Customer Second Order Of High Quality Kurkure/Cheetos/Niknak Machine At 2021 | |

| 1 | 1t/h Kurkure Making Machine In Uzbekistan |

| 2 | 1000kg/h Kurkure Making Machine For Sale In Senegal |

| 3 | Mozambique 1t/h Fully Automatic Kurkure Making Machine |

| 4 | Bangladesh 2t/h Fully Kurkure Making Machine |

| 5 | 1t/h Thai Industrial Rotary Head Extruder For Kurkure Snack Machinery |

| 6 | Uzbekistan 1t/H Rotary Head Extruder For Kurkure Snack Machinery |

| 7 | Usa 1t/h Industrial Rotary Head Extruder For Kurkure Snack Machinery |

| 8 | 800kg/h Indian Kurkur Snack Food Machine |

| 9 | Dealed Customer Have Technology Of Full Automatic New Condition Commercial Kurkur Snack Food Machine |

2021Customer Case Of Pay By T/T For Kurkure Snack Food Machine | |

| 1 | 1t/h Industrial Kurkur Snack Food Machine In Afghanistan |

| 2 | 1000kg/h Fully Automatic Kurkure Making Machine For Sale In Anguilla |

| 3 | Bahrain 1t/h Fully Automatic Kurkure Making Machine |

| 4 | Bangladesh 2t/h Fully Automatic Kurkure Making Machine |

| 5 | 1t/h Bouvet Islands Fully Automatic Kurkure Making Machine |

| 6 | Central African Republic 1t/H Kurkure Snack Processing Line |

| 7 | Colombia 1t/h Kurkure Snack Processing Line |

| 8 | 800kg/h Eritrea Spice Kurkure Snack Processing Line |

| 9 | Gambia Customer Have Technology Of Kurkure Snack Processing Line At 2021 |