35kw Power Snack Baked Kurkure Extruder Machine/ Kurkure Production Line Stainless Steel

As a professional manufacturer of Baked Kurkure Extruder Machine with rich experience, our equipment is very popular. It uses corn grits as a raw material and is squeezed by a kurkure special extruder machine into irregular strips. After baking, it can be made into delicious Baked Kurkure snacks. Nik Naks Making Machinery mainly use corn grits as material.In the flour mixer with water and fed to the rotary die extruder. In the extruder, due to excessheat andpressure from the screws the meal gets heated and the moisture content gets reduced.The meal passes through the die and gets cut by the cutting knifes into required lengths.The kurkure are fried in cooking oil and then cooled before flavoring. Seasoning is sprayed on the kurkure to improve their taste.

35kw Power Snack Baked Kurkure Extruder Machine/ Kurkure Production Line Stainless Steel Specifications :

| Price | Contact us |

| Brand Name | LOYAL |

| Place of Origin | Shandong China |

| Min.Order Quantity | 1 |

| Payment Terms | T/T,L/C,D/P |

| Supply Ability | 20 days |

| Delivery Detail | 20days--35days |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

| Warranty | 1 year |

| Machines Materials | stainless steel |

| After-sales Service | Engineers available to service machinery overseas |

| Trial Demonstratio | Welcome You To Visit Us At Any Time For Machinery |

| Automation | Fully Automatic |

35kw Power Snack Baked Kurkure Extruder Machine/ Kurkure Production Line Stainless Steel Detail Introduction :

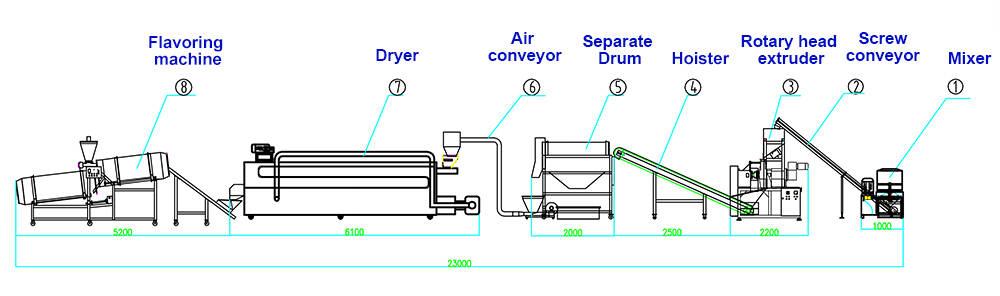

The Kurkure production line:

1. Product introduction of 35kw Power Snack Baked Kurkure Extruder Machine/ Kurkure Production Line Stainless Steel:

Cheetos is a special squeezed snack that is very crunchy in your mouth. The corn grits are mixed with a certain proportion of water and then enter the rotary head extruder.

The Kurkure production line is a new type of extruded small food production equipment. Corn strips are made of corn dregs as the main raw material. Under the squeezing and kneading action of the squeezing turntable, the irregularly twisted strips are extruded. According to customer requirements, they can be cut into products of different lengths, and then baked or fried After seasoning, corn noodles with rich flavors can be produced, which are widely favored by consumers because of their crispy, delicious, nutritious and delicious flavors.

Raw materials:

Adopts corn grits as raw materials meanwhile mixing with water and oil.

2.Specifications :

| Snack Baked Kurkure Machinery Specifications | |

| Price | Contact us |

| Brand Name | LOYAL |

| Model Number | LYK |

| Place of Origin | Shandong China |

| Min.Order Quantity | 1 |

| Payment Terms | T/T,L/C,D/P |

| Supply Ability | 20 days |

| Delivery Detail | 20days--35days |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

| Warranty | 1 year |

| Machines Materials | stainless steel |

| After-sales Service | Engineers available to service machinery overseas |

| Trial Demonstratio | Welcome You To Visit Us At Any Time For Machinery |

| Automation | Fully Automatic |

3. Main Features:

Belt transmission between motor and gear box,reducing energy consumption.

Feeding,main driving device, and rotary cutting device adopt inverter to adjust the speed with more powerful drive, stable running, and low consumption.

Screw is made of alloy steel with long life.Segmental assembled screws are applied tomore kinds of materials and products.

Automatic lubrication system can lower down power consumption and prolong the life.

Double screws feed equal materials forcibly.

Hanging mould and knives seat and bearing knife adjusting system can adjust the kniver exactly and swiftly.

4. Want to know the operation process of the Kurkure production line?

1).Mixer→ 2).Screw conveyor → 3).Rotary head extruder → 4).Hoister →5).Separate drum →6).Air conveyor→ 7).Fryer → 8). Flavoring line

(Our engineer could design the layout drawing according to your dimension of the factory for the kurkure or cheetos or nik naks machines)

Physical pictures of main parts:

1). Mixer :

| Kurkure Snacks Mixer | |

| Name | Mixer |

| Usage | To mix the raw materials evenly, fast speed, no leakage |

| Type | including Single axle and double shaft mixer |

| Motor | 3kw, 4kw, 7.5kw etc |

| Capacity | 20kg/time, 50kg/time, 100kg/time, 200kg/time, 500kg/time etc. |

| Material | stainless steel, carbon steel |

3).Rotary head extruder :

| Kurkure Snacks Extruder | |

| Name | Rotary head extruder |

Usage | To extrude the raw materials and make them to the required shape and size of kurkure |

| model | DSE65, 70, 75, 90, 95, 120, 135 |

| Motor | 22kw, 30kw, 55kw, 75kw, 90kw, 110kw etc. |

| Capacity | 100kg/h to 10 ton/h |

| Material | Screw materials 38CrMoAl stainless steel, carbon steel |

5).Separate drum :

| Kurkure Snacks Drum | |

| Name | Separate drum |

| Usage | Separating the twisted and squeenzed kurkure |

7). Dryer :

| Kurkure Snacks Dryer | |

Name | Dryer |

| Usage | Electric Belt and Upper Cover Lifting Setting .advantage of continuous production |

| Type | electrical, steam, gas fired, diesel fired heating type |

| Motor | KX-3-5, KX-5-5, KX-5-8, KX-5-10, KX-7-10 etc. |

| Capacity | 100kg/h to 10 ton/h |

| Material | stainless steel, carbon steel |

8). Flavoring line :

| Kurkure Snacks Flacoring Line | |

| Name | Flavoring machine |

| Usage | To mix the oil and flavors on the surface of the fish feed |

| Type | single and double flavoring drum |

| Motor | 0.75kw |

| Capacity | 100kg/h to 10 ton/h |

| Material | stainless steel |

5.Our Product advantages:

1). European standard, national patent, large output

2). Our 35kw Power Snack Baked Kurkure Extruder Machine/ Kurkure Production Line Stainless Steel is simple operation and easy maintenance.

3). International brand electrical devices, big brands, reliable

4). Equipped with high-efficiency and energy-saving combustion system, reasonable heat source distribution, uniform heating of materials, low energy consumption and large output.

6. Baked Kurkure extruder product parameters:

| Kurkure Snacks Parameters | ||||

| Baked Kurkure extuder machine | Installed Power | Power Consumption | Output | Size(L*W*H) |

| LY-1-B | 35Kw | 32Kw | 100-150kg/h | 17000x1100x2500mm |

| LY-2-B | 40kw | 45kw | 200-250kg/h | 17000x1100x2500mm |

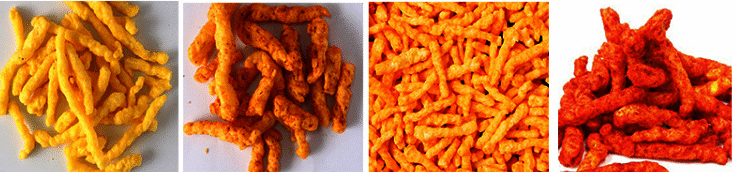

7. Sample display:

8.Why choose us?

Our Advantage:

1.Introduction of LOYAL Industrial Company

Shandong LOYAL Industrial Co., Ltd. is a professional manufacturer of catering equipment and snack food machinery. Experienced developers are helping to research new machines, design products for customers, and provide maintenance guarantees for customers in the future. 11 senior technical workers, 22 experienced engineers and 15 after-sales solution personnel will help our customers deal with all errors of our equipment within 24 hours.

We have a factory of more than 10,000 square meters. There are already branches in South Korea, Bangladesh, Spain and other regions. Our company is mainly engaged in the manufacturing, research and development of snack food machinery. According to the different needs of customers, we can provide all kinds of puffed snacks, 2D and 3D snack food production lines, potato chips, corn flakes, nutritional powder, pet food and other complete processing production lines. Our technical assistance will always help customers produce high-quality products.

2.OUR SERVICE

| 35kw Power Snack Baked Kurkure Extruder Machine/ Kurkure Production Line Stainless Steel | |

| Service for Pre-sale | Service for After-sale |

| 1.Provide technical parameter. 2.Factory layout and size suggestion. 3.Provide general formulation. 4.Custom-Design service. 5.Professional Advice about Market, machines, materials, packing. 6. Suggesting professional ship agent or helping book ship as customer request. | 1.Allocation chart as the buyer's request will be supplied. 2.Operation manual will be supplied after shipment. 3.One year warranty, lifetime maintenance, cost price. 4.Free easy broken spare parts will be sent with container. 5.First installation can be done by engineer. 6.Training workers in customer's. |

Customer Cases For Kurkur Snack Food Machine For Factory In 2021

Shandong Loyal Industrial relies on complete product specifications, excellent product quality and professional services. It has been widely recognized by customers, obtained a good brand image, has mature and stable sales channels, and accumulated a large number of high-quality customers. At present, the company's products are in short supply and are exported to Asia, Europe, North America, Africa, South America and Oceania, with customers in more than 50 countries and regions around the world. If you are interested in the Kurkur Snack Food Production Line, please contact LOYAL immediately, we will provide you with high-quality formulations of Kurkur Snack Food Production Line, professional technical process guidance, and a full range of professional market analysis.

Customer Cases For Kurkur Snack Food Machine For Factory In 2021 | |

| 1 | 1t/h Ce Certificated Industrial Energy Efficient Kurkur Snack Food Machine Sold In Russia Customer Factory |

| 2 | 1t/h Kurkur Snack Food Machine For Sale In Puerto Rico Customer Factory |

| 3 | 1t/h Kurkur Snack Food Machine Installed in Customer Factory For Sale In Bolivia Customer Factory |

| 4 | Senegal 1t/h Kurkure/cheetos/niknak corn curls machine Dryer Machine |

| 5 | 1t/h Energy Saving Large Industrial Kurkure/Cheetos/Niknak Corn Curls Machine For Sale In Côte d'Ivoire |

| 6 | China 300t/Year Tunnel Microwave Wood Dryer Timber Drying Machine |

Customer Second Order Of High Quality Kurkure/Cheetos/Niknak Machine At 2021 | |

| 1 | 1t/h Kurkure Making Machine In Uzbekistan |

| 2 | 1000kg/h Kurkure Making Machine For Sale In Senegal |

| 3 | Mozambique 1t/h Fully Automatic Kurkure Making Machine |

| 4 | Bangladesh 2t/h Fully Kurkure Making Machine |

| 5 | 1t/h Thai Industrial Rotary Head Extruder For Kurkure Snack Machinery |

| 6 | Uzbekistan 1t/H Rotary Head Extruder For Kurkure Snack Machinery |

| 7 | Usa 1t/h Industrial Rotary Head Extruder For Kurkure Snack Machinery |

| 8 | 800kg/h Indian Kurkur Snack Food Machine |

| 9 | Dealed Customer Have Technology Of Full Automatic New Condition Commercial Kurkur Snack Food Machine |

2021Customer Case Of Pay By T/T For Kurkure Snack Food Machine | |

| 1 | 1t/h Industrial Kurkur Snack Food Machine In Afghanistan |

| 2 | 1000kg/h Fully Automatic Kurkure Making Machine For Sale In Anguilla |

| 3 | Bahrain 1t/h Fully Automatic Kurkure Making Machine |

| 4 | Bangladesh 2t/h Fully Automatic Kurkure Making Machine |

| 5 | 1t/h Bouvet Islands Fully Automatic Kurkure Making Machine |

| 6 | Central African Republic 1t/H Kurkure Snack Processing Line |

| 7 | Colombia 1t/h Kurkure Snack Processing Line |

| 8 | 800kg/h Eritrea Spice Kurkure Snack Processing Line |

| 9 | Gambia Customer Have Technology Of Kurkure Snack Processing Line At 2021 |