Stainless Steel Puffed Food Extruder Machine Double Screw Extruder For Puff Snacks

The puff snacks equipment design of the production line is reasonable and the operation is simple. According to the output and investment needs, it can be equipped with a fully automatic continuous production line and a semi-automatic continuous production line. Simple structure in linear type ,easy in installation and maintation. Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts. High pressure double crank to control the die opening and closing. Running in a high automatization and intellectualization,no pollution. Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

Stainless Steel Puffed Food Extruder Machine Double Screw Extruder For Puff Snacks Especificações :

| Preço | Contact us |

| Marca | LOYAL |

| Local de origem | China |

| Quantidade Min.Order | 1 |

| Condições de pagamento | T/T,L/C,D/P |

| Capacidade de fornecimento | 100 |

| Detalhe da Entrega | 10-25 working days. |

| Detalhes da embalagem | Wooden case or wooden pellets depended on clients' require |

Stainless Steel Puffed Food Extruder Machine Double Screw Extruder For Puff Snacks Introdução detalhada :

Snack food extruder machines are pivotal in the food processing industry, transforming a wide range of ingredients into various snack products. These machines utilize high-temperature and high-pressure conditions to cook and shape raw materials such as corn meal, potato starch, or rice flour into ready-to-eat snacks like cereal, crisps, and puffed products.

How Snack Food Extruders Work

The process begins with the mixing of raw ingredients, which are then fed into the extruder’s hopper. Inside the extruder, a screw mechanism pushes the mixture through a heated barrel where it is cooked. The material is then forced through a die that shapes it into specific snack forms. As the extruded snack exits the machine, it expands and is cut to the desired size before being sent to downstream processing like flavoring or packaging.

The puff snacks equipment design of the production line is reasonable and the operation is simple. According to the output and investment needs, it can be equipped with a fully automatic continuous production line and a semi-automatic continuous production line. This puffed food extruder machine is independently developed by our company.

Design and production, can process different shapes of products according to customer requirements, can produce triangles, gourd-shaped, small fish cakes, golden horns, ducklings and other products, replace the cutting machine can process corn, large and short fragrant rice crust.

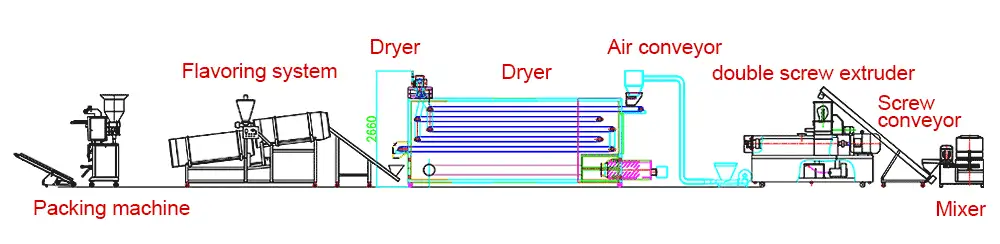

Process flow of corn puffed snack production line

Process flow: raw material preparation- Mixer→Screw conveyor→Puffed twin screw extruder→Air conveyor→Dryer→Hoist →Seasoning system→Packing machine

Semi-automatic production line equipment configuration:Mixer →Puffed twin screw extruder→Dryer→Seasoning system→packing machine

| Function Of Stainless Steel puffed Food Machine Double Screw Extruder For Puff Snacks Making Machinery | |

| Mixer | Mixing various raw materials with a motor-driven stirring cage, automatic water adding device, and pneumatic discharge valve, mixing uniformly, quickly, and without leakage. |

| Screw conveyor | Conveying material to the extruder |

| Puffed twin-screw extruder | Extrude the raw materials from the mold to produce puff snacks or other foods of the required shape and size, which is composed of a feeding system, an extrusion system, a cutting system, and a heating system. |

| Air conveyor | Conveying materials to the dryer |

| Dryer | Puffed food has a certain amount of moisture. During the drying process, the heating source can be electricity, gas, steam, and fuel. |

| Hoist | Food grade conveyor |

| Seasoning machine | Used to season food to make the final product taste more delicious and better. |

| Packaging machine | Used for final packaging of the produced food, and then sold. |

Motor data of puffed extruder food machine

| Data For Stainless Steel puffed Food Extruder Machine And Puffed Snack Samples | |

| Power Rating | 1.8W |

| AC Motor Type | Synchronous |

| Supply Voltage | 110 V ac |

| Phase | 1 |

| Output Speed | 250rpm@230V |

| Number of Poles | 24 |

| Mounting Type | Flange Mount |

| Shaft Diameter | 3mm |

| Length | 23.9mm |

| Current Rating | 18 mA |

| Rotation | Reversible |

| Maximum Output Torque | 10 mNm |

| Dimensions | 51 (Dia.) x 23.9 mm |

| Series | 9904 |

Features of corn puffed snack production line:

| Features of corn puffed snack production line | |

| 1 | The design is reasonable, the structure is compact, and the operation is effortless. |

| 2 | The operation is highly automated. Only one or two people can complete the processing process, saving manpower. |

| 3 | Stable performance and reliable quality. It is carefully researched and developed by a professional team to meet the needs of food processing. |

| 4 | Low cost, high efficiency, low energy consumption to ensure the whole process from feed to finished product. |

| 5 | The machine's output can be changed by configuring more extruders on one production line to meet higher output requirements. |

| 6 | All machines are made of stainless steel, and the screws are made of alloy steel, with a modular system structure and self-cleaning function. |

How to make corn puff snacks easily?

The corn puffed snack production line adopts PLC operating system and advanced mechanical structure to realize fully automated production-continuous feeding, automatic flattening, automatic cutting, and cross-cutting. Compared with traditional hand-made methods, it reduces a lot of production costs and improves production efficiency.

By changing the raw material formula, the corn puffed snack production line can produce many different products. The shape of the corn flakes can be round, square, semi-circular, and triangular.

FAQ:

Q: What productivity per hour of puffed food extruder machine

A: 100-150kg/h,200-250kg/h...

Q:cost of equipment?

A:The cost is calculated based on the output and others you need. Our price is

relatively cheap in the industry

Q: Is the equipment ready in the warehouse or will you manufacture? If made,

how many days will it take?

A:Most of the equipment is in stock, depending on whether the product you

make is special

Q:Prepayment of 30% or 50% of the cost?

A:40% Down Payment By T/T In Advance, The Balance 60% Should Be Paid

Before Delivery. (After We Sign The Contract, You Pay The 40% Deposit,

And Then The Contract Comes Into Effect.)

Q: What forms are there of corn puffed snack production line?

A: We can produce the products on the picture, which one do you want?

The corn puffed snack production line is another type of small food production line after the puffed food production line. It uses corn starch and potato starch as the main raw materials and uses the extrusion molding process to achieve the sensory effect of the product shape. The product shape is natural and realistic, and the texture is delicate. The taste is loose, not cracked or scattered.

The production line has a good design, strong stability, and a high degree of automation. The host adopts frequency conversion speed regulation technology to ensure the stable quality of processed products. It is a combination of traditional technology and modern technology. The products include spirals, potato chips, shrimp cracks, shells, round tubes, Dozens of kinds of snails, circles, waves, foams, etc., are available.

Customer cases for snacks making machine for factory in 2021

| Customer cases for snacks making machine for factory in 2021 | |

| 1 | 1t/h cost of snacks making machine sold in russia customer’s factory |

| 2 | 1t/h industrial snack maker machine price for factory for sale in puerto rico puffy snack plant agent |

| 3 | 1t/h industrial snack maker machine price for sale in bolivia customer’s factory |

| 4 | Senegal 1t/h industrial fully automatic industrial snack maker machine |

| 5 | 1t/h snacks making machine price for sale in côte d'ivoire |

| 6 | China 300t/year industrial fully automatic snacks making machine price |

| Customer case of snack food making machine at 2021 | |

| 7 | 1t/h microwave drying equipment for factory in uzbekistan puffy snack machinery agent |

| 8 | 1000kg/h snack maker machine for sale in senegal customer’s factory |

| 9 | Mozambique 1t/h fully automatic snacks making machine price |

| 10 | Bangladesh 2t/h fully automatic snacks making machine price |

| Dealed customer have technology of corn puff extruder machine at 2021 | |

| 11 | 1t/h thai snack food making machine for factory |

| 12 | Uzbekistan 1t/h fully automatic corn puff extruder machine |

| 13 | Usa 1t/h corn puff extruder machine |

| 14 | 800kg/h industrial snacks making machine for sale in nigeria customer agent |