Macaroni Production Line is Widely Used

There are many types of macaroni on the market. Nowadays, macaroni is generally processed and produced on a macaroni production line. It is a new type of macaroni production equipment designed and developed to meet the needs of the market and meet the needs of consumers and processing plants. The application of macaroni has increased the production speed of macaroni and has been recognized by more and more users.

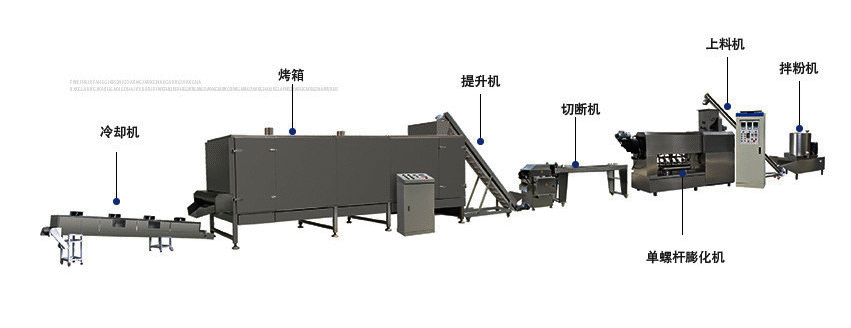

The Macaroni Pasta Production Line is mainly composed of mixer, conveyor, extruder, conveyor cutting machine, hot air dryer, cooler, and packaging machine. The host is equipped with high and low pressure screws, which increases the scope of use of raw materials and reduces costs. Improved product quality, from the mixing of product raw materials to the packaging of finished products at one time, with a high degree of automation.

Features of the macaroni production line:

1. The whole line has reasonable design, fully automatic production and accurate control.

2. The screw material is 38CrMoAl, wear-resistant and durable.

3. All machines are made of stainless steel to extend the service life.

4. The food produced by this production line by changing molds is high-quality and high-quality food.

5. The main raw material is flour, which can be used to make macaroni, shell-shaped food, square food, round food, spiral food, etc.

All models of the macaroni production line can be equipped with different specifications of blades. Therefore, one machine can produce different specifications of macaroni according to different specifications of knives. By changing the mold, it can also produce different types and different shapes of products. Multi-purpose, good versatility.

The working principle of the macaroni production line is similar to that of the noodle machine. The noodle machine squeezes the flour into a dough through the relative rotation of the flour roller, and then cuts the dough into strips through the front head to form noodles. The macaroni production line first mixes the raw materials uniformly, then sends them to an extruder to be extruded, and then is dried and cooled, and finally the finished product is packaged.

The macaroni production line is a new type of advanced equipment. The machine is continuous from feeding to outputting finished products. The degree of automation is very high. It is very convenient to operate, saves time and effort, and is simple to operate. It only needs one to two people to complete the processing and production of macaroni. Work, save time, and production efficiency has been significantly improved.

The design of this production line is very reasonable. It is carefully built by professional designers, combined with previous manufacturing experience, listened to customers’ opinions, and has undergone repeated transformation and improvement. All of them are the most advanced in the world. The machine parts and equipment are compact in structure and the quality is guaranteed.

All parts of the production line show excellent performance, and the machine parts of each part are the most advanced. Therefore, the entire production line works very efficiently, which can meet the different needs of food processing and bring great convenience to food processing plants, to bring them considerable economic benefits.

The products processed by the macaroni production line are of very high quality. During the production process, no pollutants are produced. The macaroni produced meets food safety and sanitation standards and is very healthy. Moreover, in the process of processing, there is no loss of nutrients, and the food made with it can supplement some of the nutrients needed by the human body.

In general, Macaroni Pasta Production Line is perfect in terms of appearance, performance, and quality. Its appearance, excellent performance, reliable quality, and reasonable price make it a good product at a reasonable price. It is believed that with the development of society and the advancement of science and technology, it will be better improved, and its application will become more and more common.