Multi-function Stainless Steel Spaghetti Pasta Macaroni Machine, Macaroni Production Line

The macaroni extrusion line can produce macaroni in various shapes and sizes. Through different molds, it can produce snack foods with a variety of patterns, such as screws, hollow rods, shells, numbers, wheels, flowers, etc. It is mainly made of wheat flour, making the product tough and chewy. Our company has improved the pasta machine persormance by means of the marketing research and our own technology and makes the operator operate the machine easily and make the craft more perfect. The whole Pasta Production Line is automatic and continuous. The automatic Pasta Production Line is suitable for the mixing of raw materials to the final packaging for sale. It has simple operation, moderate output, energy saving and high efficiency, small floor space, low investment, and quick results. The macaroni production machine is especially suitable for start-up companies. The Pasta Production Line ranges from raw material ingredients, mixing raw materials, conveying, extrusion, and baking to a complete product. Fully automatic industrial macaroni production machine can produce all kinds of pasta and macaroni food.

Multi-function Stainless Steel Spaghetti Pasta Macaroni Machine, Macaroni Production Line Specifications :

| Price | Contact us |

| Brand Name | LOYAL |

| Place of Origin | China |

| Min.Order Quantity | 1 |

| Payment Terms | T/T,L/C,D/P |

| Supply Ability | 100 |

| Delivery Detail | 20days--35days |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

Multi-function Stainless Steel Spaghetti Pasta Macaroni Machine, Macaroni Production Line Detail Introduction :

1. Introduction of Multi-funtion Stainless Steel Spaghetti Pasta Macaroni Machine:

Macaroni pasta is making after extruding, slaking, forming, drying, and inflating. Our company has improved the pasta machine persormance by means of the marketing research and our own technology and makes the operator operate the machine easily and make the craft more perfect. This is indispensable production food equipment for everyone taking on the food profession. Multi-function Stainless Steel Spaghetti Pasta Macaroni Machine is characterized by unique technique, rational configuration, high automation and stable performance. It can finish steaming, extrusion and shaping in one step without boiler.

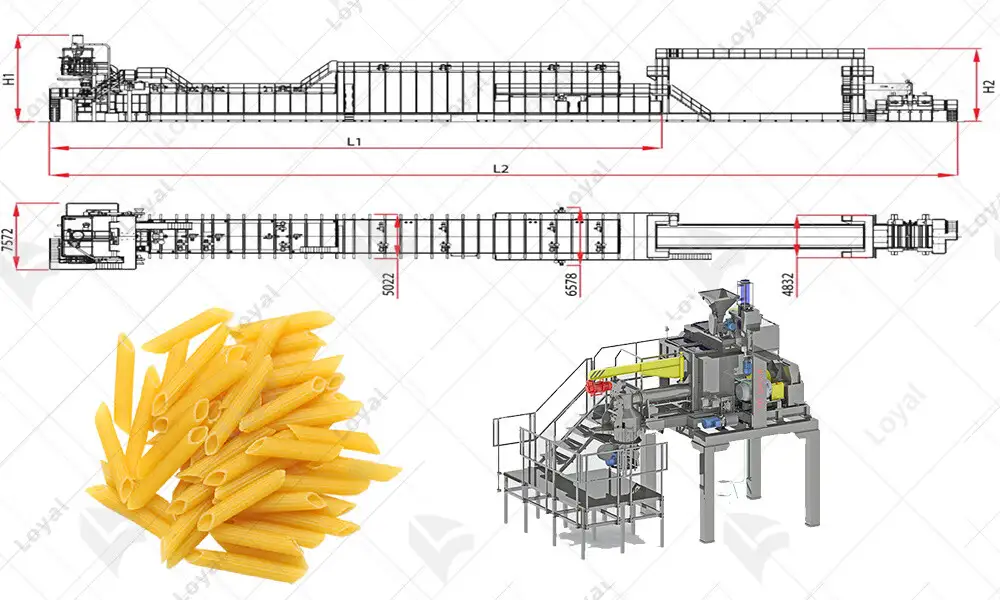

The Macaroni Production line can use wheat flour as main material to make different shapes pasta, like tube, elbow, screw, shell etc. Equipment configuration is perfect, advanced production technology; good quality products, simple and reliable operation; is the ideal equipment to make macaroni.

2. Flow chart of Multi-funtion Stainless Steel Spaghetti Pasta Macaroni Machine:

1).Mixer→ 2).Screw Conveyor→ 3).Vacuum Extruder→ 4).Pulling And Cutting Machine→ 5).Hoister→ 6).Multi-Layer Dryer→ 7).Cooling Conveyor

3. Machine Details about the Macaroni Production Line :

1). Vacuum Extruder:

| Vacuum Extruder Detail | |

| 1.Feeding System: | Installed in the main machine, which feeds materials spirally, and the quantity can be adjusted. This system includes engine, screw, blender and machine shelf. |

| 2.Extruding System: | The materials are matured by using processes such as mixing, cutting and vacuum extrusion, and the temperature of the drum and screw is strictly controlled to achieve the required indicators of the materials. |

| 3. Cutting System: | The shelf is fixed on the head of the moulds; and turns and cuts the materials motivated by the belt wheel. |

| 4.Heating System: | Divides five areas, and the heating temperature of which can be adjusted separately. |

| 5.Transmitting System: | The motive power from the main engine is transmitted to the screw through the triangle belt and decelerator. |

| 6.Controlling System: | Can control all the components of the main machine centrally. |

2). Multi-layer Dryer:

1.Compact in frame, facilitated in operation, low occupation of space and high heating efficient.

2.Stainless steel is used on conveying belt, oven cover to guarantee the food safe.

3. Rock wool plates are used for heat preservation.

4. The drying time for the product can be adjusted by a frequency converter.

5. Forced lubrication system to lengthen the bearing life.

4. Main Features About The Macaroni Production line:

| Main Features about The Macaroni Production line |

| 1). Adopts stainless steel punching plate type chain plate structure, which is durable. |

| 2). Both sides of the belt to ensure that the material does not leak sideways. |

| 3). The insulation boards around are all open-door type, with high temperature resistant sealing strips. |

| 4). All bearings are isolated from the high-temperature gas in the box, in a low temperature area. |

| 5). Adopt high-temperature-resistant fan to force the hot air circulation, hot air from bottom to top, even drying, obviously improve the drying efficiency. |

| 6). The bottom plate of the oven adopts a slope shape, which is easy to clean. |

| 7). The mesh belt adopts frequency conversion which is convenient for speed regulation. |

| 8). With distributing machine, the raw materials are evenly distributed on the conveyor belt. |

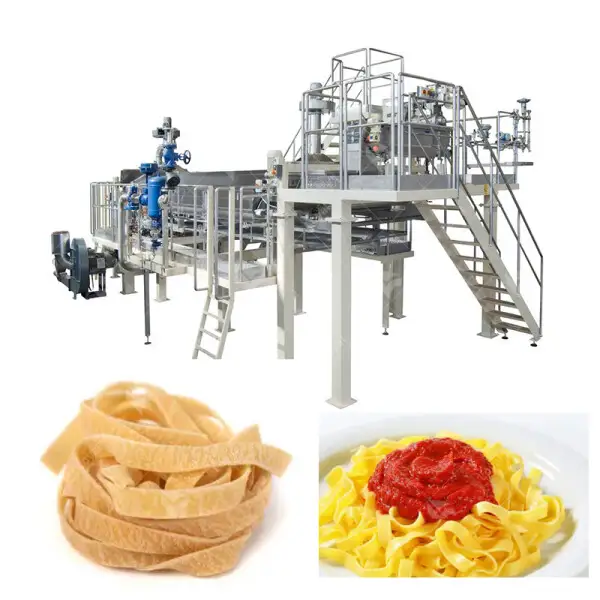

5. Sample Pictures About Pasta :

6.We Will Provide Best And Thoughtful Service For You :

a.) Consultation service before, during, and after sales.

b.) Project planning and design service.

c.) Debugging of equipment until everything is functional.

d.) Management of equipment’s long distance shipping from seller's factory to the named place by buyer.

e.) Training of equipment maintenance and operating personally.

f.) New production techniques and formulas.

g.) Provide 1 year complete warranty and life-time maintenance service.

FAQ:

| Question | Answer |

| Are you a trade company? | Our company is in an integrated set of industry and trade company. |

| Do you provide the formula to the customers? | Yes, we usually provide the formula for our customers and other services. |

| Which machine can be selected for the customer? | We can provide the customized services according to our customers' demands. |

| What is the applicable voltage and frequency of the whole production line? | We can according our customer's local voltage to provide the customized services. |

| Do you provide the samples? | Yes. We can provide the samples for our customers. Also we are welcome our customers can visit our factory. |

| How about the after-services? | We have the professional after-services department to deal with all kinds of problems from our customers and offer all kinds of services for our customers. |

| What is the material of the machine? | Stainless steel, especially parts contacting with materials, conforming to food grade. |

Packing and delivery

• Inside package is plastic film, outside is wooden or plywood case (based on the customers’ need).

• Only plastic film nude packing with wooden pallet.

• We can supply fumigation package and certificate.

• Shipping, train, express or upon clients' demands.

Which Market Did The Loyal Spaghetti Line Sold?

| Customer Case Of Spaghetti Pasta Production Line At 2021 | |

| 1 | Old thailand Customer of 500kg/ h Automatic New Type Spaghetti Pasta Production Line in new Pasta Processing Plant |

| 2 | 1T/H Tough Spaghetti Pasta Production Line For Sale in Puerto Rico |

| 3 | 1T/H Crisp Spaghetti Production Line For Sale in Bolivia |

| Dealed Customer Have Technology Of Spaghetti Pasta Production Line At 2021 | |

| 1 | Senegal 1T/H Industrial Spaghetti Production Line |

| 2 | 1T/H Spaghetti Machine for Sale in Côte d'Ivoire |

| 3 | 1T/H Industrial Spaghetti Equipment Sold in Russia |

| Dealed Customer Have Formula Of Automatic Spaghetti Process Line At 2021 | |

| 1 | 1000kg/h Industrial Automatic Spaghetti Machine For Sale In Senegal |

| 2 | Mozambique 1t/h Industrial Spaghetti Manufacturing Line |

| 3 | Bangladesh 2t/h Industrial Spaghetti Making Machine |

| 2021 Automatic Spaghetti Process Line customer with factory | |

| 1 | Bangladesh 2t/h Industrial Spaghetti Making Machine |

| 2 | 800kg/h Industrial Spaghetti Production Line For Sale In Nigeria |

| 3 | Algerian Spaghetti 300kg/h Production Line |