Textured Vegetable Protein Manufacturing Processing Line

Textured Vegetable Protein Manufacturing Processing Line is developed independently according to the requirement of market and on the base of advanced machinery in Switzerland and America. The main raw materials of soya chunks processing machine are non-fat soybean meal and peanut meal. After stirring and squeezing, layer fiber tissue is formed. Its product protein content is high, with the state and taste of meat, with the characteristics of oil absorption, water absorption, and taste absorption; Free of cholesterol and animal fat. The textured vegetable protein food can be widely used in meat products, fast food, frozen foods, and can also be made into a variety of vegetarian casual foods and vegetarian dishes.

The Detail Descriptions Of The Textured Vegetable Protein Manufacturing Processing Line

| No. | Item | Details Description of soya chunks processing machine |

| 1 | Raw materials | Defatted soya meal, isolated soya protein,low temperature soya meal, peanut meal, wheat gluten and isolate soy powder, and additives, etc. |

| 2 | Capacity | 100-150kg/h, 120-160kg/h, 200-300kg/h, 300-400kg/h, 400-500kg/h, 1000kg/h, etc. |

| 3 | Consumption | Low electricity and labor consumption. |

| 4 | Machine materials | Stainless steel |

| 5 | Final products | This line can be used to produce soya nuggets, TVP/TSP, soya chunks, soya pieces, soybean fibers by adjusting the molds from extruder; meanwhile it can produce cereal, snacks by adjusting the screws from extruder. |

| 6 | Application | Soya protein food is widely add into ham, sausage, can food, fast food and deep freeze food for more taste. |

What Is The Advantages Of The Textured Vegetable Protein Soya Chunks Nuggets Production Line?

1.Various models to meet different output capacity requirements.

2. Flexible configurations to meet different produce, budget and workshop layout requirement.

3. Vast raw material range to produce different final products by only one production line

4. Different shapes and appearances of final products can be made by changing different modules in extruder.

5. High automation and accurate control system to save labor cost and improve the quality of final products.

Technical Parameter Of Full Automatic Soya Badi Making Machine

| Model | Extruder Power | Output | Extruder Dimension |

| LY65-TVP | 45 kw | 100~150kg/h | 3600x1000x2000mm |

| LY 65 | 45kw | 120~160kg/h | 3200×1000×1800mm |

| LY 75-TL | 140 kw | 200~300kg/h | 5200x1000x1900mm |

| LY 75-E | 125 kw | 400~500kg/h | 5900x1000x1900mm |

| LY 85-V | 110 kw | 300-400 kg/h | 5900x1000x1900mm |

LY 100 | 160 kw | 1000kg/h | 5700*1300*2500mm |

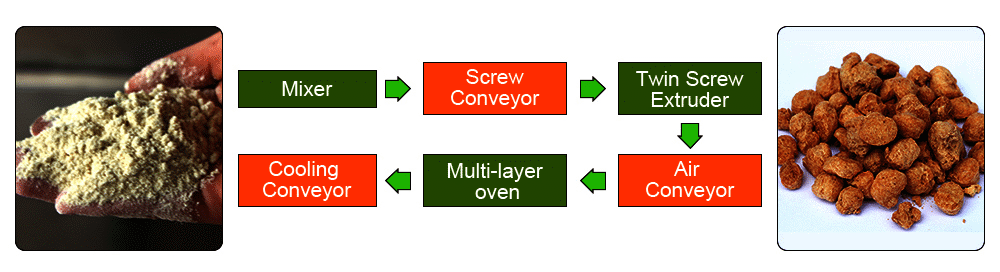

Flow Chart Of The Commercial Soya Badi Making Machine

Mixer- Screw conveyor- Twin Screw Extruder- Air conveyor- Dryer- Cooling Conveyor-Packing Machine

Process of Textured Soya Protein Vegetable Nuggets Food:

a) Mixing materials

b) Extruding different shape soya protein vegetable by changing the die

c) Drying to remove moisture

d) Cooling

Layout For Textured Vegetable Soya Protein Nuggets Processing Line Soyabean Badi Making Machine

Our Technician team can design the soya protein vegetable meat analogue machine layout according to your factory size and dimension.

What Is The Main Features Of The Textured Vegetable Soya Protein Machine Soya Chunks Processing Machine ?

| 1 | Screw made by nit-riding process, high strength and wear-resting. |

| 2 | Self-cleaning ability, no need to discharge or clean the barrel and screw when roasting or replacing of materials. |

| 3 | Adopting speed adjusted converter on feeding system, extrusion system and cutting system. |

| 4 | Food grade stainless steel twin screw feeding machine, stable materials feeding in the whole food process. |

| 5 | Gearbox with automatic lubrication function, extending gear life. |

| 6 | World famous brand Siemens main motor, guaranteeing good quality. |

| 7 | Increased radiator on driving part for forced cooling effect, ensuring extruder operates safely. |

| 8 | Barrel with water-cooled circulation, raw materials not only for corn/rice, also for wheat flour/starch with high viscosity. Different moisture-extrusion temperature ratio, whole-expanded and half expanded as different type of products. |

| 9 | Different screw and length-diameter ratio can meet different production processes. |

What Is The Applications Of The Textured Vegetable Protein Manufacturing Processing Line?

1.Soyabean badi soya chunks processing machine uses soybean powder and peanut powder to break spherical protein molecule to form chain protein molecule .

2.This kind of food has high nutrition and can be widely applied in many industries: ham, cam, fast-food, instant-cool food etc.

3.Final products can be:

Dry Textured soya protein Pellets, Crumbs, Minced, Flakes, Chunks, Chips ,Schnitzel, Nuggets.

High moisture wet protein Soya, Pea, Pea-sunflower