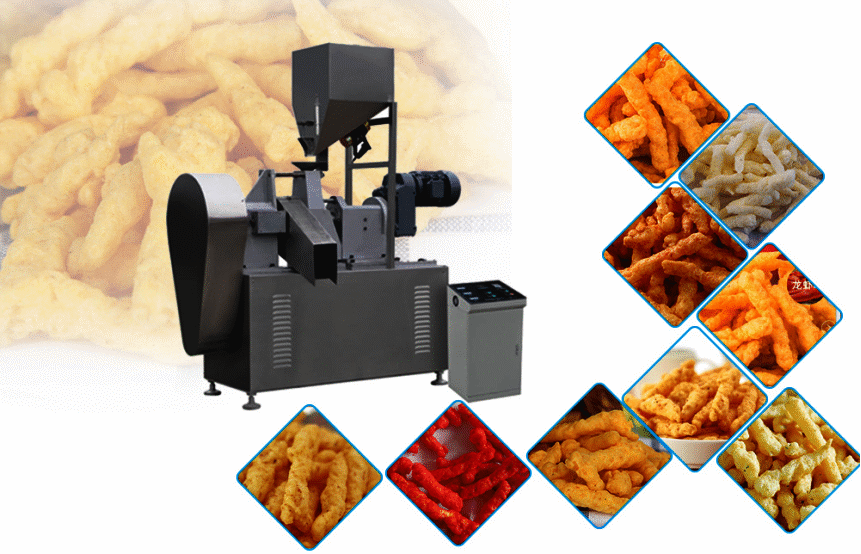

FULL AUTOMATIC FRIED CHEETOS KURKURE MAKING MACHINE ROTARY HEAD EXTRUDER PRICE

Kurkure making machine uses corn dregs (corn dregs) as raw materials and is extruded by the host to produce irregular puffed foods. After seasoning, they can be made into crispy products with different tastes, which are deeply loved by consumers.Nik Naks Making Machinery mainly use corn grits as material.In the flour mixer with water and fed to the rotary die extruder. In the extruder, due to excessheat andpressure from the screws the meal gets heated and the moisture content gets reduced.The meal passes through the die and gets cut by the cutting knifes into required lengths.The kurkure are fried in cooking oil and then cooled before flavoring. Seasoning is sprayed on the kurkure to improve their taste.

FULL AUTOMATIC FRIED CHEETOS KURKURE MAKING MACHINE ROTARY HEAD EXTRUDER PRICE Especificaciones :

| Precio | Contact us |

| Nombre de la marca | LOYAL |

| Lugar de origen | China |

| Cantidad minima para ordenar | 1 |

| Términos de pago | T/T,L/C,D/P |

| Capacidad de suministro | 1000 |

| Detalle de Envio | 3days--7days |

| detalles del empaque | Wooden case or wooden pellets depended on clients' require |

FULL AUTOMATIC FRIED CHEETOS KURKURE MAKING MACHINE ROTARY HEAD EXTRUDER PRICE Introducción detallada :

Kurkure making machine uses corn dregs (corn dregs) as raw materials and is extruded by the host to produce irregular puffed foods. After seasoning, they can be made into crispy products with different tastes, which are deeply loved by consumers. The extruder uses a vibrating feed hopper and can adjust the flow of raw materials. The feed screw speed is controlled by frequency conversion and can be adjusted arbitrarily. The mechanical gear linkage realizes the manual control of the extruder head gap, and the handwheel controls the linkage of the machine base to make it easier for the feeding screw to enter the extruder barrel.

FEATURES OF CHESTNUT STRIP ROTATING HEAD EXTRUDER:

1. The corn stick production line is divided into two processes: frying and baking

2. The latest rubbing and squeezing technology makes the product crisp and delicious.

3. Exquisitely designed and precise control system.

4. The key parts are made of brass, which has good abrasion resistance.

5. Vibrating feeding makes the feeding even and adjustable.

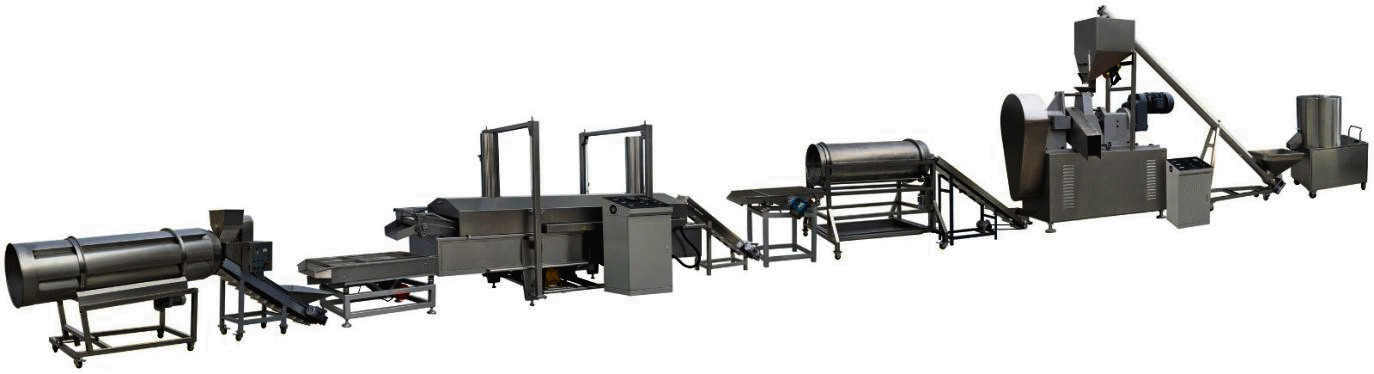

Single screw food production line includes single screw baking type production line and single screw frying type production line.

①Fried kurkure making machine

Process flow: mixing → feeding → squeezing → deslagging → frying → seasoning → packaging

Equipment configuration: powder mixer → screw conveyor → rotating head extruder → hoist → drum screen → continuous fryer → single drum seasoning line → packaging machine

②Roasted kurkure making machine:

Process flow: mixing → feeding → squeezing → conveying → baking → seasoning → packaging

Equipment composition: powder mixer → screw conveyor → rotating head extruder → air conveyor → continuous mesh belt oven → drum seasoning machine.

YIELD TABLE OF KURKURE MAKING MACHINE

| Model | Output | Size (L*W*H) |

| Fried kurkure extruder machine | ||

| LY-1-F | 125-140kg/h | 17000x1100x2500mm |

| LY-2-F | 200-230kg/h | 17300x1200x2600mm |

| Baked kurkure extruder machine | ||

| LY-1-B | 125-140kg/h | 16000x1100x2500mm |

| LY-2-B | 200-230kg/h | 16300x1200x2600mm |

Powder mixing machine: The motor drives the mixing shaft to rotate at a high speed, so that the raw materials in the powder mixing machine are fully mixed evenly, about once every 7 minutes.

According to the needs of the product, various raw materials, rice flour, cocoa powder, flour, corn flour, soybean flour and other grain flours, a small amount of water is mixed in different proportions according to different products, and some chemical additives, such as calcium carbonate, baking powder, can also be added. Pigment etc.

The mixing shaft in the powder mixing machine can rotate at a high speed, and the mixing shaft is close to the wall of the barrel, which can reduce material accumulation.

There is a funnel on the powder mixer, which is mainly used to put some liquids, such as water and oil. This is because when the lid is opened and the machine is running, the centrifugal stirring force is large, and there is dust, and the material is fed from the hopper to avoid dust.

Screw conveyor: The motor drives the screw to convey the material from the powder mixer to the feeder at the upper end of the extruder. The volume of the hopper on the screw conveyor can be modified according to customer requirements. The screw conveyor can be conveyed horizontally or at any angle. These materials can be conveyed in the stainless steel drum without leakage and dust pollution.

Rotary head extruder: When the material enters the barrel, due to the friction between the barrel and the screw, coupled with the spiral structure of the screw, during high-speed rotation, there will be a high temperature and high pressure in the closed environment of the barrel. , Causing the material to mature. When the material is pushed to the discharge port of the front section of the barrel, it is extruded and puffed through the die holes of different shapes on the die.

Air conveyor: The air conveyor is composed of three parts: fan + bucket + bobbin. The air conveyor uses a fan to blow the material into the tube and transport it to the oven.

Oven: According to the requirements of the output, there are different layers such as single layer, three layers, five layers, and seven layers. Electric heating is installed with heating pipes, and the price of oil and gas equipment is the same, but the burner is different. The mesh belt and guard plate are made of food-grade stainless steel, and the operating speed of the oven is controlled by frequency conversion, which is stable and can be used for a long time. The temperature is controllable. When heating, a precise temperature probe is installed in the heating zone to ensure that the temperature error is small and affect the product. The dryer is equipped with a dehumidification system to effectively discharge moisture and air.

Seasoning line: the product comes out of the oven to the elevator, enters the drum, the oil sprayer sprays the oil on the product, and rolls and stirs in the drum to ensure that there is oil on the surface of the product, and the seasoning can be sticky.

Customer Cases For Kurkur Snack Food Production Line For Factory In 2021

Shandong Loyal Industrial relies on complete product specifications, excellent product quality and professional services. It has been widely recognized by customers, obtained a good brand image, has mature and stable sales channels, and accumulated a large number of high-quality customers. At present, the company's products are in short supply and are exported to Asia, Europe, North America, Africa, South America and Oceania, with customers in more than 50 countries and regions around the world. If you are interested in the Kurkur Snack Food Production Line, please contact LOYAL immediately, we will provide you with high-quality formulations of Kurkur Snack Food Production Line, professional technical process guidance, and a full range of professional market analysis.

Customer Cases For Kurkur Snack Food Machine For Factory In 2021 | |

| 1 | 1t/h Ce Certificated Industrial Energy Efficient Kurkur Snack Food Machine Sold In Russia Customer Factory |

| 2 | 1t/h Kurkur Snack Food Machine For Sale In Puerto Rico Customer Factory |

| 3 | 1t/h Kurkur Snack Food Machine Installed in Customer Factory For Sale In Bolivia Customer Factory |

| 4 | Senegal 1t/h Kurkure/cheetos/niknak corn curls machine Dryer Machine |

| 5 | 1t/h Energy Saving Large Industrial Kurkure/Cheetos/Niknak Corn Curls Machine For Sale In Côte d'Ivoire |

| 6 | China 300t/Year Tunnel Microwave Wood Dryer Timber Drying Machine |

Customer Second Order Of High Quality Kurkure/Cheetos/Niknak Machine At 2021 | |

| 1 | 1t/h Kurkure Making Machine In Uzbekistan |

| 2 | 1000kg/h Kurkure Making Machine For Sale In Senegal |

| 3 | Mozambique 1t/h Fully Automatic Kurkure Making Machine |

| 4 | Bangladesh 2t/h Fully Kurkure Making Machine |

| 5 | 1t/h Thai Industrial Rotary Head Extruder For Kurkure Snack Machinery |

| 6 | Uzbekistan 1t/H Rotary Head Extruder For Kurkure Snack Machinery |

| 7 | Usa 1t/h Industrial Rotary Head Extruder For Kurkure Snack Machinery |

| 8 | 800kg/h Indian Kurkur Snack Food Machine |

| 9 | Dealed Customer Have Technology Of Full Automatic New Condition Commercial Kurkur Snack Food Machine |

2021Customer Case Of Pay By T/T For Kurkure Snack Food Machine | |

| 1 | 1t/h Industrial Kurkur Snack Food Machine In Afghanistan |

| 2 | 1000kg/h Fully Automatic Kurkure Making Machine For Sale In Anguilla |

| 3 | Bahrain 1t/h Fully Automatic Kurkure Making Machine |

| 4 | Bangladesh 2t/h Fully Automatic Kurkure Making Machine |

| 5 | 1t/h Bouvet Islands Fully Automatic Kurkure Making Machine |

| 6 | Central African Republic 1t/H Kurkure Snack Processing Line |

| 7 | Colombia 1t/h Kurkure Snack Processing Line |

| 8 | 800kg/h Eritrea Spice Kurkure Snack Processing Line |

| 9 | Gambia Customer Have Technology Of Kurkure Snack Processing Line At 2021 |

Kurkure Snack Machinery Working Process Video