What is the Biscuit Production Line?

Snack food occupies the mainstream of mass consumption and is the most important presence in the daily life of modern consumers. No matter what class or age group, they all love biscuits very much.

Biscuits are also a kind of fast-moving consumer goods with a very broad market. But now, consumers have more stringent requirements on the production process of biscuits, and only high-quality biscuits will be recognized by consumers. Therefore, after careful consideration, we decided to upgrade our equipment to use the Biscuit Production Line in order to improve our production process further.

What is a Biscuit Production Line?

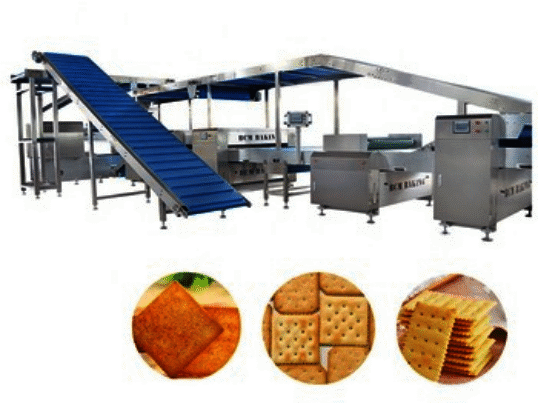

As the name implies, a biscuit production line is a complete set of equipment used to produce biscuits. It consists of a combination of equipment, including mixers, conveyors, elevators, roller presses, baking machines, cooling lines, and packaging machines. When purchasing, you can buy the whole line and one of the machines according to your needs, which is a great convenient for us.

When using this production line to produce biscuits, all production processes from feeding to cooling and packaging can be completed automatically. In addition, the thickness of the cookies can be adjusted, the rotation speed of the machine can be adjusted, and the automatic temperature control system can automatically adjust the temperature, which is very convenient to use.

When we use biscuit equipment, we need to go through the following processes to produce biscuits:

1. Mix flour, sugar, oil, milk, and other ingredients according to the recipe, add the right amount of water and then mix well in the mixer.

2. The mixed ingredients are conveyed by the conveyor into a roller press, where the dough is first pressed into sheets and then cut into shapes.

3. The formed cookies are baked in the oven at a high temperature.

4. After baking, the cookies need to be cooled, and when they are cooled to room temperature, the packaging will not return to moisture and will always maintain a crispy texture.

5. The packaging machine is used for packaging.

It can be seen that in the production process, each piece of equipment plays a very important role, and a complete process can be formed under the coordination of multiple parties to produce high-quality biscuits.

After using the cookie machine for production, our enterprise production capacity has been rapidly improved, and the economic efficiency has also been effectively enhanced. The equipment has very many significant advantages.

Advantages of the cookie machine:

1. Stainless steel material, sturdy and durable, long use time.

2. Fully automatic production method, high production efficiency.

3. Can process and produce many types of cookies, widely used.

4. Small energy consumption in the production process, no pollution, no waste.

5. The PLC control system is easy to operate, and only 1-2 people are needed to ensure the smooth production of the whole line.

The advantages of the Biscuit Production Line are apparent. In addition, there are many advantages, which bring many conveniences to our processing and production, and further expand our market scale. The manufacturer has also developed many different models to meet the needs of more cookie factories.

Model and technical parameters of biscuit equipment:

Model | Power | Voltage | Capacity | Required Labor | Size |

01 | 50kw | 380v | 100-150kg/h | 1-2 people | 1.4*0.8*1.3m |

03 | 70kw | 380v | 150-200kg/h | 1-2 people | 1.5*0.9*1.4m |

05 | 100kw | 380v | 250-300kg/h | 1-2 people | 1.6*1.0*1.5m |

07 | 120kw | 380v | 300-350kg/h | 1-2 people | 1.7*1.2*1.5m |

09 | 200kw | 380v | 500-800kg/h | 2-3 people | 2.0*1.5*1.8m |

The production line has many models to choose from, and the voltage and power can be customized, making it the best right-hand man for the biscuit factory.

With the help of this production line, our enterprise has entered a rapid development stage, not only providing consumers with delicious cookies but also allowing our employees to get a good salary. Therefore, after a period of use, we think the cookie equipment is very reliable and hope that the cookie industry will see greater development with our joint efforts!