How to Produce Soya Protein?

Product Description

Soya protein machine is a new type of puffed food production line developed by our company in line with the needs of the food market. The textured protein uses soybeans, defatted soybean meal, etc. as the main raw materials, and products with different protein content can be produced by changing the formula.

After being extruded by an extruder, protein products with different structures and shapes can be obtained, such as soybean nuggets, textured protein, soybean crushes, etc. The produced fiber product has better water absorption and is by far the best substitute for animal meat. Textured protein does not contain cholesterol and animal fat, so it is widely used in the meat industry, fast food production, frozen food production and various snacks.

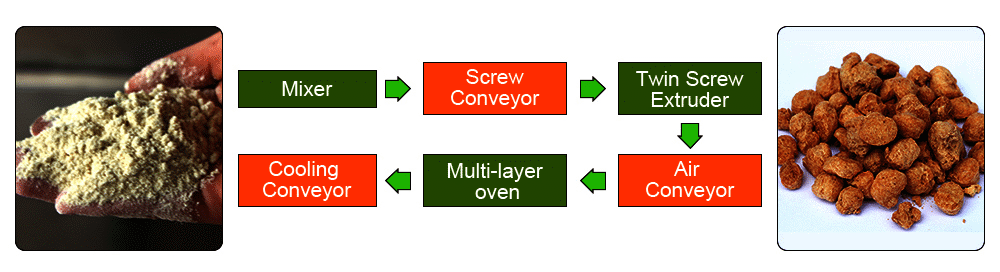

Flow Chart of Soya Nugget Machine

Flour Mixer-Screw Hoister-Double Screw Extruder-Hoister-Oven-Cooling Conveyor-Packing Machine

Soya Nugget Machine Consist---

| NO. | Product Name | Function |

| 1 | Flour Mixer | Mixing raw materials, water, additives |

| 2 | Screw Hoister | The screw conveyor can be conveyed horizontally or at any angle. The materials are conveyed through stainless steel rollers without leakage and dust pollution. |

| 3 | Double Screw Extruder | To cook the soyabean meal and extruded in different shapes. The machine is composed of a feeding system, an extrusion system, a rotary cutting system, a heating system, a transmission system, and a control system. It adopts advanced screw extrusion technology and uses high temperature and high pressure to mature and expand the material into one-time completion. |

| 4 | Hoister | Deliver the product to the oven |

| 5 | Oven | The oven is a multi-layer circulating dryer, can reduce the moisture of extruded protein snacks. |

| 6 | Cooling Conveyor | This equipment is used for product cooling. To cool down the extruded protein snacks and send to next equipment. |

| 7 | Packing Machine | Pack the soya protein in different size bags. |

Product Parameter of Soya Chunks Making Machine

| Model | InstalledPower (KW) | Power Consumption (KW) | Capacity (KG/H) | Dimension (M) |

| LY65 | 74KW | 52KW | 100-150KG/H | 17*1.2*2.2M |

| LY70 | 95KW | 70KW | 200-300KG/H | 20*1.5*2.2M |

| LY85 | 139KW | 102KW | 300-500KG/H | 28*3.5*4.3M |

| LY95 | 200KW | 160KW | 800-1200KG/H | 35*3.5*5.5M |

Main Features of Soya Chunks Making Machine

1)Direct transmission between motor and gear box,reducing energy consumption.

2)Feeding, main driving device, and rotary cutting device adopt inverters to adjust the speed with more powerful drive, stable running, and low consumption.

3)Screw is made of durable alloy steel. Segmental assembled screws are applied to more kinds of materials and products.

4)Automatic lubrication system slows down power consumption and prolong the usage life.

5)Double screws feed equal materials forcibly.

6)Hanging molds(dies) and knives seat and bearing knife adjusting system can adjust the knife exactly and swiftly.

7)Low production cost and high profit.

8)The materials can be reorganized and shaped into different shapes such as pipe, stick, ball and more.

Health Benefits of Soya Protein

1.Most health experts believe that eating more plant-based foods and eating less animal-based foods will have a positive impact on human health. Therefore, choosing organized vegetable protein instead of meat will be a healthy choice.

2.Soy protein provides all the amino acids needed by humans. Because it is a complete source of protein, some medical experts recommend it as a potentially healthier alternative to meat. In fact, studies have shown that eating soy can lower cholesterol and reduce the risk of cardiovascular disease.

3.In addition, eating soybeans can also help improve menopausal symptoms, increase bone density and reduce the risk of fractures in menopausal women.

What Can Chunks Making Machine Processing?